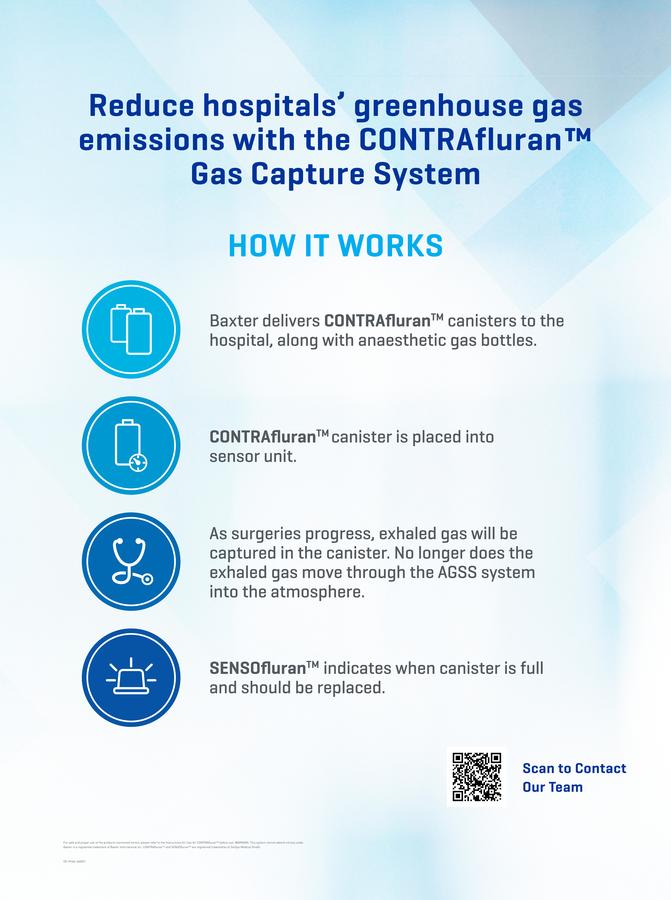

How CONTRAfluran™ Works

Overview of the CONTRAfluran™ system

Gives you clinical flexibility by adsorbing Suprane (desflurane, USP), sevoflurane, or a mixture of both.1

CONTRAFluranTM Gas Capture absobs 99% it recieves8

CONTRAfluranTM is a specially designed canister that contains a highly porous carbon filter derived from coconuts.

To use CONTRAfluran™, attach a canister and the proprietary SENSOfluranTM sensor unit to the anesthesia machine in passive mode.

Then, operate as usual

The patient's exhaled gas travels into the canister and is absorbed by the filter. The sensor will indicate when the canister needs to be replaced.

Your hospital’s potential savings

Environmental

With careful consideration of the impact of healthcare, CONTRAfluranTM can help reduce a hospital’s carbon footprint.2

Social

By improving the patient experience and minimizing the need for resource intensive care we can allow you to deliver the right anesthetic, in the right place at the right time.

Economic

You can design the best quality operative care possible with CONTRAfluranTM captures fast-acting anesthetic desflurane, allowing patients a faster wake up time, potentially reducing hospital cost.3,4

Use the CONTRAfluranTM Gas Capture System with or without the AGSS5,6

Baxter offers two sensor units - the SENSOfluranTM, which does not connect to the AGSS, and the SENSOfluran CONNECT which does connect to the AGSS in the operating theatre.

If using nitrous oxide, the SENSOfluran CONNECT must be used and the AGSS must stay on.

SENSOfluran CONNECT allows the CONTRAfluranTM canister to capture Sevoflurane and desflurane, and vents nitrous oxide to the AGSS.

Ready to turn off your AGSS?

SENSOfluranTM has such efficient adsorption that it essentially captures volatile gas escape, so you can turn the AGSS off.

The AGSS is a significant contributor to energy consumption in the operating theatres and critical care units. Turning it off leads to cost savings from reduced energy usage and maintenance.7

WARNING: CONTRAfluranTM / SENSOfluranTM CONNECT cannot adsorb, capture or detect nitrous oxide. Since CONTRAfluranTM CANNOT adsorb nitrous oxide, the system must be connected correctly to the operating room AGSS gas removal system to ensure safe removal of non-adsorbed gases. CONTRAfluranTM and SENSOfluranTM are only indicated for use with fluorinated halocarbon anaesthetic gases (sevoflurane, desflurane and isoflurane).

Daily anesthesia-related electrical energy use (kWh) in a single OT7

18.03 kWh are estimated anesthetic gas scavenging use

5.00 kWh are estimated anesthetic room radiant heater use

3.52 kWh is the mean measured operating theatre use

1.73 kWh is the mean measured anesthetic room use

Appropriate Use5

The CONTRAfluranTM Anesthetic gas canister is intended to remove fluorinated halocarbons (such as sevoflurane, desflurane and isoflurane) in operation rooms, intensive care units, and mobile or ambulatory treatment areas, regardless of the type of exhaust device used. The CONTRAfluranTM Anesthetic gas canister is designed exclusively for these applications.

The SENSOfluranTM and SENSOfluran CONNECT control units must only be used in combination with the CONTRAfluranTM Anesthetic gas canister during sedation and operation of patients using volatile anesthetics.

Please note that the canister and fill level control unit must only be used by qualified personnel.

Important safety information

CONTRAfluran with SENSOfluran Standard

CONTRAfluran with SENSOfluran CONNECT

For safe and proper use of the products mentioned herein, please refer to the complete Instructions for Use.